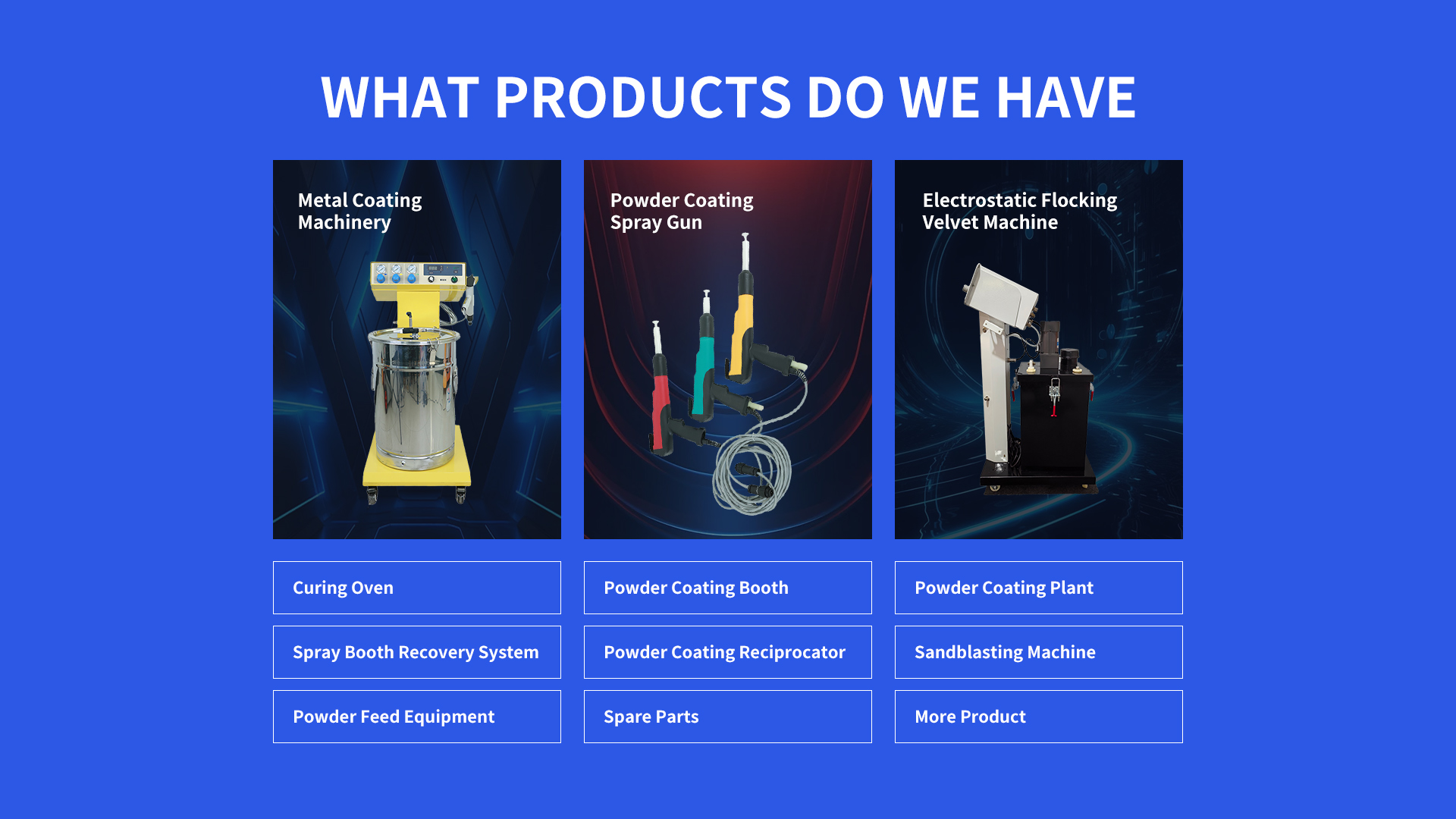

1. Introduction and Structure of Powder Spray Coating Line Suppliers' EquipmentPowder Spray Coating Line Suppliers provide comprehensive systems. A standard line features a reliable conveyor for transporting workpieces. The spray booth, equipped with high-performance spray guns, is where powder application occurs. The curing oven ensures precise temperature control for powder fusion. Additionally, a powder recovery unit and an intelligent control panel are integral parts, enabling efficient powder recycling and process monitoring.

2. Application Scenarios of Powder Spray Coating Line Suppliers' Equipment

These lines are highly versatile. In the aerospace industry, they coat aircraft components for corrosion resistance and to enhance aerodynamic properties. For metal fabrication businesses, they offer durable finishes for structural parts. In the appliance manufacturing sector, powder spray coating lines from suppliers are used to coat metal parts of refrigerators, stoves, etc., for protection and aesthetics.

3. Price of Powder Spray Coating Line Suppliers' EquipmentThe cost of equipment from

Powder Spray Coating Line Suppliers varies. Basic lines for small-scale operations can start at around $25,000. Mid-range lines with enhanced features and higher productivity typically range from $40,000 to $80,000. High-end, large-capacity lines with advanced technology can cost over $80,000.

4. Correct Usage Method of Powder Spray Coating Line Suppliers' Equipment

Begin by properly placing workpieces on the conveyor. Adjust spray gun settings like powder flow and electrostatic charge according to the powder and workpiece specifications. Preheat the curing oven to the recommended temperature. Continuously monitor the coating process as workpieces move through the line and make adjustments as needed. Once cured, unload the workpieces carefully.

5. How to Select Equipment from Powder Spray Coating Line SuppliersWhen choosing equipment from

Powder Spray Coating Line Suppliers, assess your production scale. Ensure the line has sufficient capacity. Examine the quality of key components such as the spray guns and conveyor. Look for suppliers with a good reputation for after-sales support. Also, consider the energy consumption and powder recovery efficiency of the line.

6. Safety Precautions of Powder Spray Coating Line Suppliers' Equipment

Safety is paramount. Workers should wear appropriate protective gear, including respirators, gloves, and safety goggles, to prevent powder inhalation and skin/eye exposure. Ensure proper ventilation in the spray booth to avoid powder dust buildup. Keep the equipment away from flammable substances and regularly check electrical connections for any issues.

7. Rationality Analysis of Powder Spray Coating Line Suppliers' EquipmentInvesting in equipment from

Powder Spray Coating Line Suppliers is a wise decision. It boosts production efficiency, cuts labor costs, and ensures consistent coating quality. The powder recovery system reduces material waste, saving costs in the long run. The advanced design of the line allows for adaptability to different products and coating requirements.

8. Q&A about Powder Spray Coating Line Suppliers' Equipment

Q1: Can I upgrade the equipment from powder spray coating line suppliers?

A: In many cases, yes. Suppliers often offer upgrade options for components like spray guns or control systems. You can consult with the supplier to see what upgrades are available for your specific powder spray coating line equipment.

Q2: How does the powder recovery system of equipment from powder spray coating line suppliers work?

A: The powder recovery system uses filters or cyclones to separate powder from the air within the spray booth. The collected powder is then recycled back into the system, reducing waste and saving on powder costs for the powder spray coating line equipment.

Q3: What's the difference between entry-level and high-end equipment from powder spray coating line suppliers?

A: High-end equipment offers better precision in powder application, faster production speeds, more advanced control features, and greater durability. Entry-level equipment is more basic and suitable for small-scale or less demanding applications of powder spray coating line equipment.

Q4: Is it easy to install the equipment from powder spray coating line suppliers?

A: Installation difficulty varies. Some suppliers provide detailed installation manuals and even offer installation services. Smaller, simpler lines may be easier to install, while larger, more complex lines from powder spray coating line suppliers may require professional installation.

Q5: How often should I replace the filters in the powder spray coating line equipment from suppliers?

A: The frequency of filter replacement depends on usage. In general, it's advisable to check and replace filters every few months or when they show signs of clogging to maintain the efficiency of the powder spray coating line equipment.

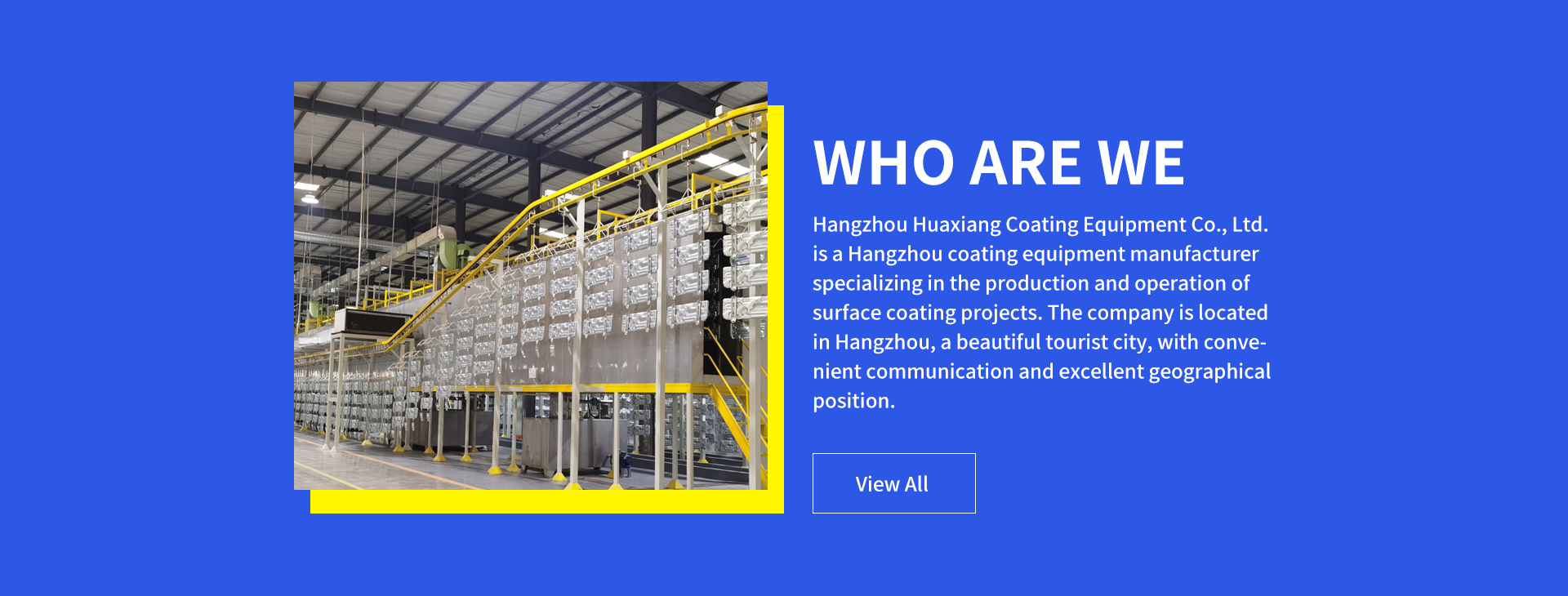

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com